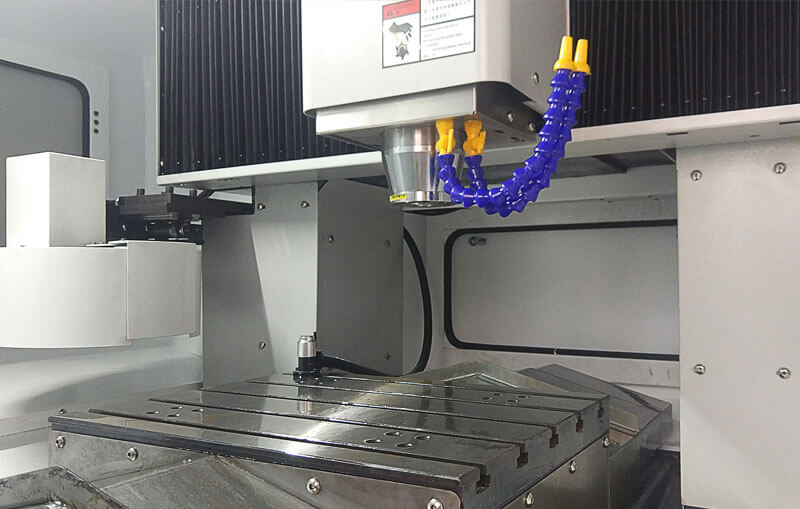

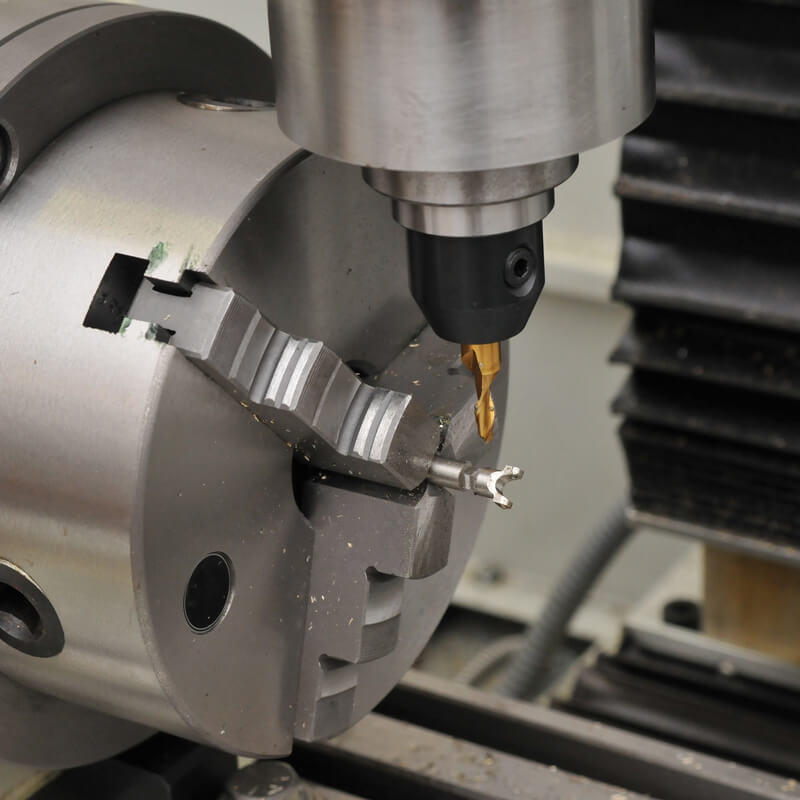

The structure of CNC milling machine / vertical machining center is optimized, compact and reasonable, and the rigidity is strengthened. It can realize the processing of various disc, plate, shell, cam, mold and other complex parts, and can complete various processes such as drilling, milling and tapping. It is suitable for the production of batch products and can meet the processing of drilling, tapping and milling processes of small and medium-sized workpieces.

Processing of various metals (such as die steel, stainless steel, carbon steel, aluminum alloy, magnesium alloy, titanium alloy, brass, red copper, etc.) and non metals (nylon, saigang, acrylic, bakelite, peek, PE, Pei, ABS, plexiglass, Teflon PTFE, PC, POM, etc.). And provide vacuum heat treatment, carburizing, nitriding, carbon steel blackening, sand blasting, anodizing (Puyang, hard Yang), titanium plating, chromium plating, silver plating, vibration grinding, polishing, silk screen printing, laser and other one-stop services.

| Processing Range | |||

| Aluminum | Al1060 Al5052 Al5083 Al5086 Al6061 Al7075 t6 h111 h112 h321 |

Aluminum alloy | |

| Copper | H52 H56 H62 | Bronze | Brass |

| Steel | Q235 Q235B | ||

| carbon steel | AISI45 45# S45C | ||

| Stainless Steel | SUS201 SUS303 SUS304 SUS306 SUS316 | ||

| POM,nylon,Teflon\PTFE\F4,Bakelite,PEEK,HDPE,ABS,PP | |||

| carbon fibre | |||

view more...

| Processing Range | Dust free constant temperature workshop | |

| Rapid Prototyping | Turned | Centerless grinding |

| Micro Machining | Milled | Concentric grinding |

| CNC Machining | Broaching | PGA grinding |

| CNC turning | Grinding | Gong tooth |

| CNC milling | Bend | Wire drawing |

| Laser Machining | Drilling | Polishing |

| 4&5 Axis CNC Machining | ||

| 4&5 AxisWire cutting | ||

| Electrical Discharge Machining | ||

| surface treatment | electroplate | |

| grinding | Chrome plating | |

| polishing | Cadmium plating | |

| flame-treated | Tinning | Hard anodized |

| acid washing | Nickel plating | sand blasting |

| water cutting | Galvanized | anodic oxidation |

| hone finished | Gold-plated | |

| polished finished | Silver plating | |

| sand-sprayed | Copper plating | |

| brush-hammered | Phosphating | |

| edge polishing | Vacuum coating | |

| bevel edge | Tungsten Carbide | |

| carburizing/carburization | ||

| nitriding | ||

| Zirconia Ceramic | ||

| Blackening treatment | ||

| stress-relieve treatment | ||

| Tempering treatment |

| Purpose | Mechanical | Turnkey project |

| Metal Components | Automation equipment | Bicycle |

| Parts | Standardized equipment | Electric vehicle |

| Accessories | Non standard equipment | Motorcycle |

| Shaft | Sealing packaging machine | Automobile |

| Metal fixture | Automatic winding machine | Agricultural vehicle |

| Gear | Production line | Tractor |

| Rollerxxx | Fitness Equipment | Balance car |

| Thimble | Aerospace equipment | Watch |

| Rubber covered roller / wheel | Ship equipment | UAV |

| Marine equipment | Ship | |

| Medical equipment | Metal jewelry | |

| Bracket | ||

| Latch |

Automobile and motorcycle Bicycle parts, aerospace, instruments and meters, automation equipment, electronic and electrical appliances, health care products, digital products, communication, medical treatment, optics, lighting, monitoring, photography, models, remote control aircraft, golf, outdoor, diving, toys, fishing gear, electronic cigarette, PTZ, intelligent lock, optical lens, radiator, stage lighting equipment, etc.

Provide fast proofing (1 piece from order), small batch and batch production; Provide samples in 2-3 days as soon as possible, small batch and batch production are nearly 7-10 days, and the delivery rate is 96%; Can provide inspection report and accept quality review; Mass production, good product consistency and competitive price.

A. The process of batch parts is continuously improved to reduce costs and win market and competitiveness for customers;

B. Provide high-precision parts, high-quality parts, easily deformed parts, and some complex processing and manufacturing services.