Generally, five axis linkage refers to the linear interpolation motion of any five coordinates in X, y, Z, a, B and C. Compared with the common three-axis (x, y and Z degrees of freedom) machining, five axis machining means that when machining parts with complex geometry, the machining tool needs to be able to locate and connect on the five degrees of freedom.

The machine tool used in five axis machining is usually called five axis machine tool or five axis machining center. Five axis machining is often used in the field of automobile, ship and aerospace to process mechanical parts, turbine parts and impellers with free-form surfaces. The five axis machine tool can process different sides of the workpiece without changing the position of the workpiece on the machine tool, which can greatly improve the processing efficiency of prismatic parts.

| Machine tool model | LJ-400T | LJ- SOOT | LJ- 630T | LJ- 800T |

| Bed Dimension(mm) | 740x460 | 840x540 | 1020x640 | 1180x750 |

| Worktable stroke(mm) | 400x320 | 500x400 | 630x500 | 800x630 |

| Maximum size of workpiece(mm) | 680x460 | 820x520 | 980x600 | 1200x700 |

| Maximum thickness of straight line cutting(mm) | 260 | 260 | 350 | 350 |

| Maximum weight(kg) | 300 | 500 | 800 | 1200 |

| Minimum instruction unit of X and Y(mm) | 0.001 | 0.001 | 0.001 | 0.001 |

| Z-axis slip vertical ” trip(mm) | 250 | 250 | 300 | 300 |

| Taper U, V axis stroke(mm) | ±30x±30 | ±30x±30 | ±30*±30 | ±30x±30 |

| The host of(kg) | 1500 | 1800 | 2200 | 2800 |

| Machine Overall Dimension(length•width•height) | 1700x1300x2160 | 1960x1620x2160 | 2120x1760x2250 | 2410x2060x2250 |

| Package dimensions(length♦width•height) | 2010*1400x2300 | 2220x1800x2300 | 2350x2000x2400 | 2800x2100x2400 |

| Maximum cutting taper | ±6° /80nun | |||

| U, V Minimum instruction unit(mm) | 0.001 | |||

| Control Mode | Step hybrid or servo drive | |||

| The Z axis transmission | Ac reduction motor up and down | |||

| Number of linkage control axes | X、Y、U、V four-axis | |||

| Diameter of storage drum | 0155mm | |||

| Maximum stroke of silk drum(mm) | 200 | |||

| Suitable diameter of electrode wire(mm) | 00.16 - 00.20 (Standard Configuration 00.18mm) | |||

| Wire walking speed(mm) | l-11.4m/s变频可调 | |||

| Maximum silk storage length(mm) | 250 | |||

| Machining Precision(mm) | ^0.01 | |||

| Maximum cutting speed(mnf/min) | S150 | |||

| Optimum machining surface roughness(urn) | RaW 1.0 (A cut two repair) | |||

| The tank configuration | High pressure slow wire filtration,volume 150L | |||

| Working liquid filtration method | Paper core fine overfilling | |||

| control system | HL2. HF2. HT2、Autocut. Wincut | |||

| power supply | three phase 380V ± 10%/50HZ | |||

| Total power consumed by machine tools(kw) | 2.3/6 | |||

| Maximum working current | 6A | |||

| Machine machine noise | £ 70dB | |||

| Purpose | Mechanical | Turnkey project |

| Metal Components | Automation equipment | Bicycle |

| Parts | Standardized equipment | Electric vehicle |

| Accessories | Non standard equipment | Motorcycle |

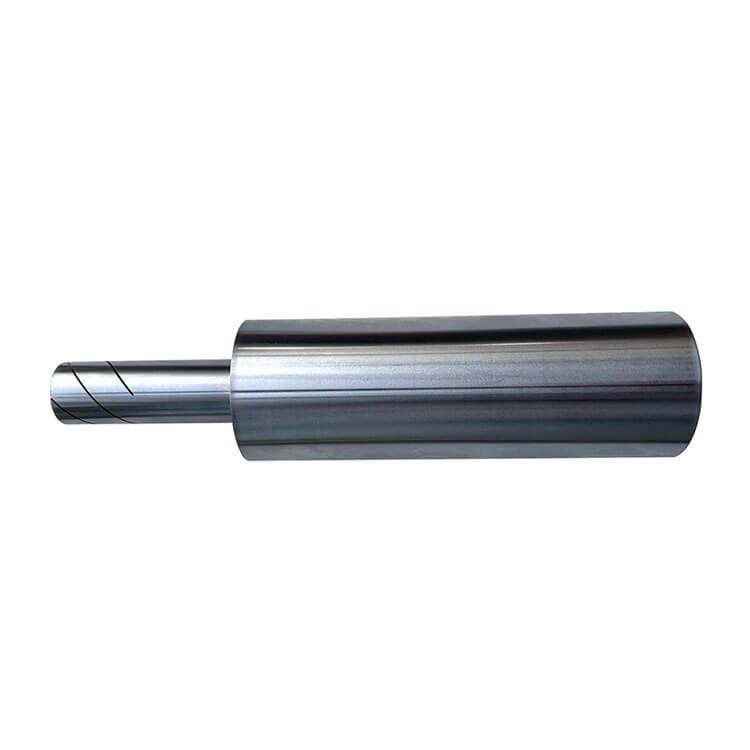

| Shaft | Sealing packaging machine | Automobile |

| Metal fixture | Automatic winding machine | Agricultural vehicle |

| Gear | Production line | Tractor |

| Rollerxxx | Fitness Equipment | Balance car |

| Thimble | Aerospace equipment | Watch |

| Rubber covered roller / wheel | Ship equipment | UAV |

| Marine equipment | Ship | |

| Medical equipment | Metal jewelry | |

| Bracket | ||

| Latch |

Automobile and motorcycle Bicycle parts, aerospace, instruments and meters, automation equipment, electronic and electrical appliances, health care products, digital products, communication, medical treatment, optics, lighting, monitoring, photography, models, remote control aircraft, golf, outdoor, diving, toys, fishing gear, electronic cigarette, PTZ, intelligent lock, optical lens, radiator, stage lighting equipment, etc.

A. The process of batch parts is continuously improved to reduce costs and win market and competitiveness for customers;

B. Provide high-precision parts, high-quality parts, easily deformed parts, and some complex processing and manufacturing services.