| No. | Name | Process content | Use equipment |

| 1 | Turning | Use Φ 35mm column material, clamp one end, and turn the other end to the outer circle φ 24mm, length 8mm; Outer circle dimension to φ 33mm, length 9mm. | Turning |

| 2 | Turning | Clamp machined outer circle φ 24mm, outer circle of the other end of the vehicle to φ 21mm, with a guaranteed length of 32mm. | Turning |

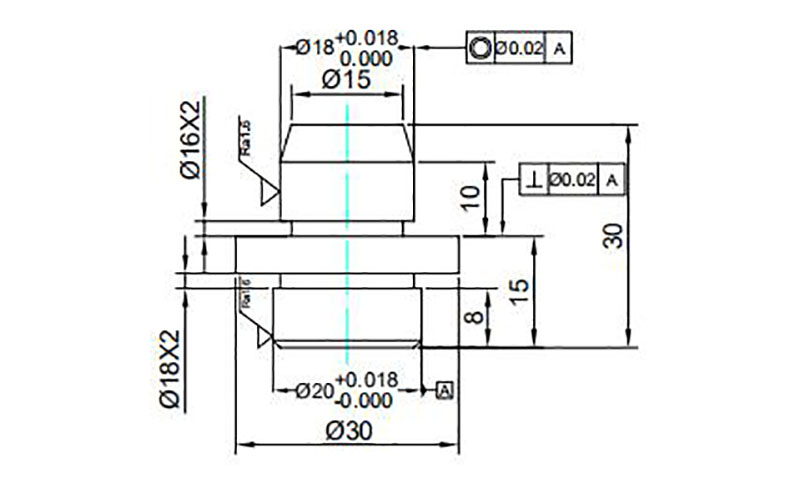

| 3 | Precision turning | With φ 21mm outer circle positioning and clamping, and the outer circle size is to φ 20mm, 10mm long, cutting back the groove φ 18x2mm, turn the end face to ensure the outer circle size. Drill the center hole A2. | Turning |

| 4 | 4 Precision turning | With φ 20mm outer circle positioning and clamping, and the outer circle size is to φ 18mm, length size 5mm, cutting back the groove φ 16x2mm, turn the end face, ensure the outer circle size, and drill the center hole A2. | Turning |

| 5 | Heat treatment | Heat treatment hardness 55 ~ 60HRC | |

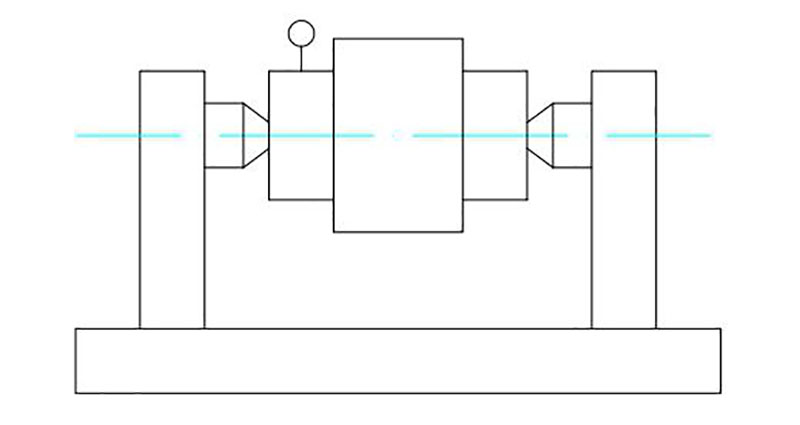

| 6 | Precision grinding | Position and clamp the workpiece with the center hole A2, grind and process the two shaft diameters to meet the drawing size requirements, and grind the two end faces to ensure the perpendicularity | Grinding |

| 7 | Testing | Inspect the dimensions of each part according to the drawing requirements | Pendulum, Micrometer |

This kind of relatively simple parts, we have rich technical experience, customers are very assured to give us to make.

*The cases we show here have been agreed by the customers.