Machine tool industry provides "machine tool" to machinery industry, which is the foundation of machinery industry. The mainstream product of modern machine tool industry is CNC machine tool. It integrates the technology of various disciplines, has the characteristics of high efficiency, high precision, high automation and high flexibility, and is developing in the direction of intelligence and integration. It is the foundation and core of contemporary machinery manufacturing industry.

Pneumatic technology, fully known as pneumatic transmission and control technology, is one of the effective means of production process automation and mechanization. It has the advantages of high speed and efficiency, safety, long life, easy maintenance and anti overload. It is being more and more widely used in many fields of industrial departments.

In CNC machine tools, pneumatic technology is mainly used in the following devices because it is easy to realize high-frequency commutation, speed regulation in a large range, save space and volume,

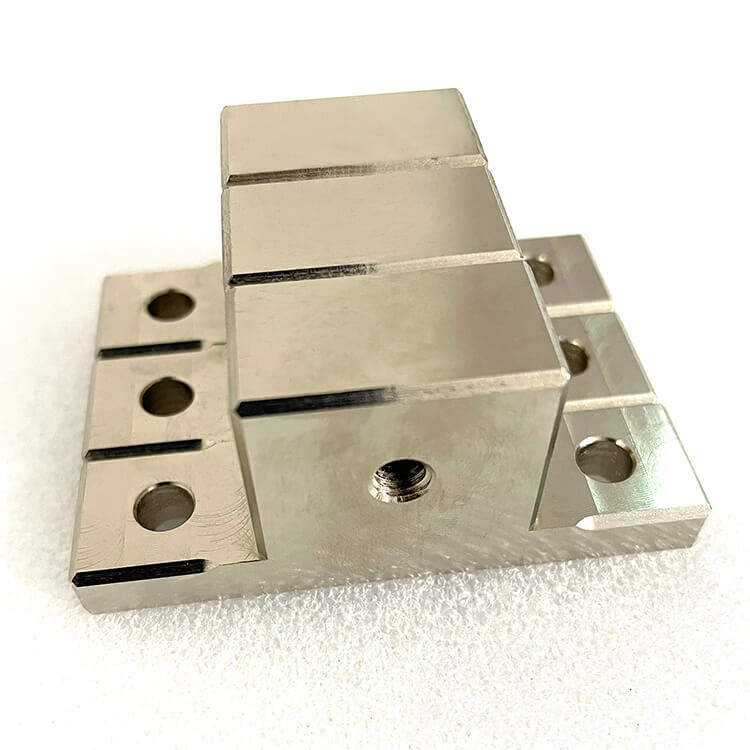

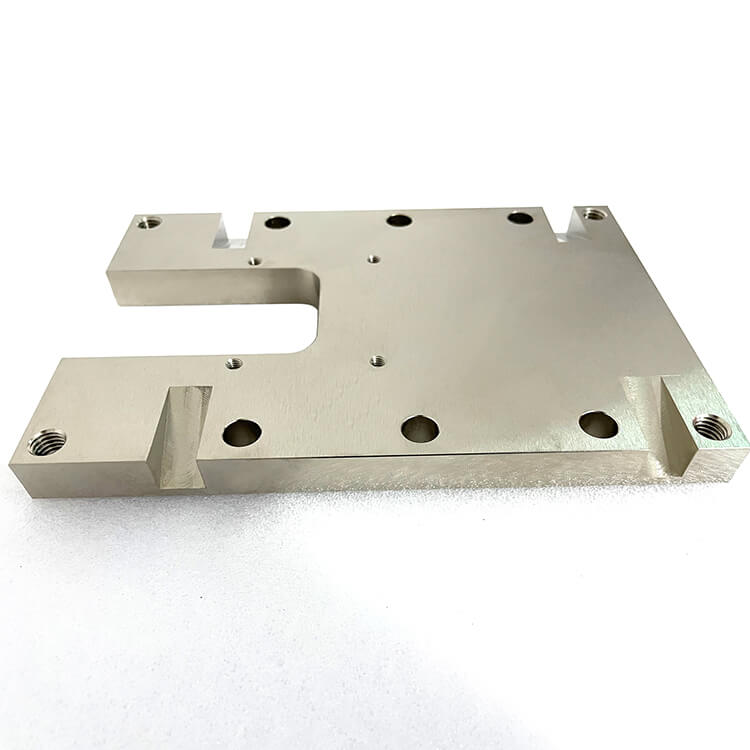

Supporting metals, such as aluminum alloy, magnesium alloy, copper, etc; Processing of non-metallic materials, such as ABS, plexiglass, Teflon PTFE, peek, PC and saigang POM; Provide sand blasting oxidation, electroplating, paint baking, plastic spraying, silk screen printing, laser, spraying and other post-treatment processes;

1. The movement of machine tool parts is mainly used for feed motion transmission, such as the movement of spindle and worktable.

2. Auxiliary devices in CNC machine tools, such as fixed cycle, automatic tool change, clamping and loosening of worktable, opening and closing of automatic door, air blowing, workpiece clamping, automatic loading and unloading of workpiece, transportation and stacking, can shorten the processing auxiliary time, reduce the labor intensity of workers and give full play to the efficient performance of CNC equipment.

3. Automatic chip blowing, such as workpiece, exchange workbench, tool positioning surface, etc.

4. Balance of moving parts, such as gravity balance of headstock, manipulator, balance device of tool magazine, etc.

5. Detection function, such as confirmation of workpiece position, confirmation of tool defect, etc.